Common Faults of the Dynapic Paver machine

As a China-based leader in road construction, equipment maintenance, and paver machine parts sales with 10+ years’ expertise, we offer OEM, aftermarket, and refurbished asphalt paver machine parts with extended warranties. Enjoy free replacements during warranty periods. Our wholesale program provides cost-effective solutions for all paver machine spare parts.

Below are common paver failures and solutions:

1. Hydraulic Oil Overheating

Excessive oil temperature degrades viscosity, accelerates wear, and damages seals. Solutions:

1. Check oil levels → Refill immediately

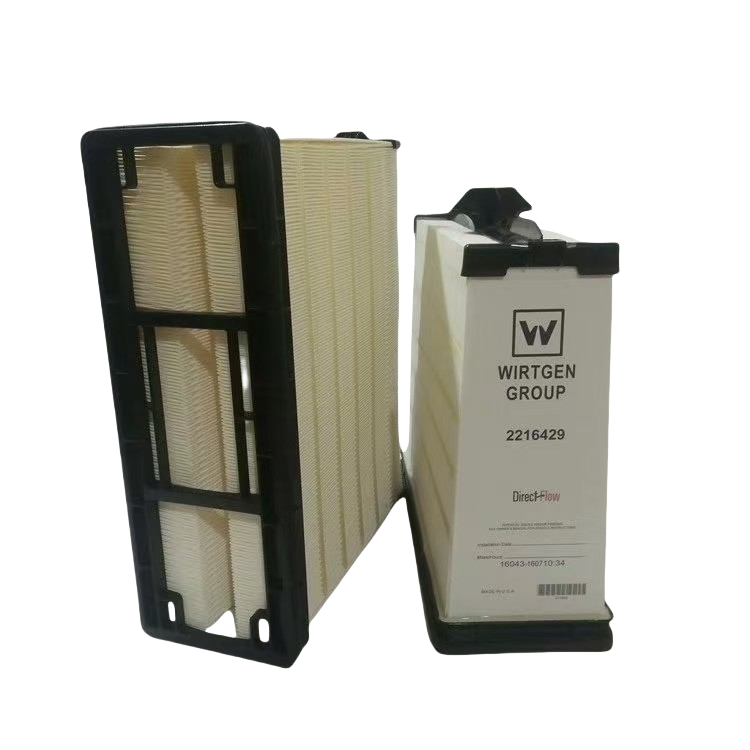

2. Inspect parts of the paver machine like clogged filters/cores

3. Clean radiator dust buildup (critical in dusty environments)

4. Verify oil quality; replace if substandard

5. Examine pumps/motors after oil refills

2. Vibration System Failure

Symptoms: Poor compaction quality, system malfunction.

Root Causes:

Damaged vibration wheel

Hydraulic cylinder leakage

Electrical wiring faults

Solutions:

1. Replace worn vibration wheel components

2. Inspect hydraulic cylinders; seal/replace leaking units

3. Test wiring continuity; repair/replace damaged circuits

3. Spiral Distributor Failure

When left/right distributors stall:

1. Inspect paver machine parts name: worn distributor bearings → Replace + lubricate

2. Check chain stretch → Replace over-elongated chains

3. Test planetary reducers → Replace gear assemblies if worn

4. Diagnose hydraulic pumps/motors via pressure gauges → Replace faulty units

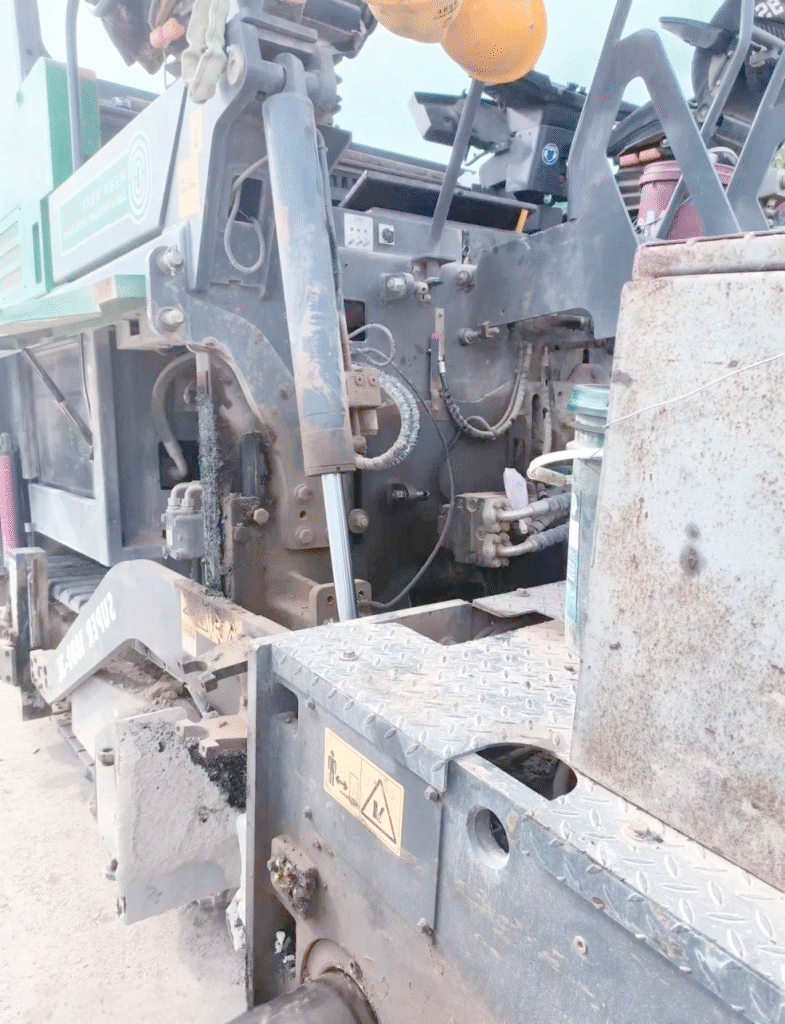

4. Travel System Failure

Symptom: Sluggish movement or complete immobility.

Root Causes:

1. Low tire pressure

2. Malfunctioning travel motor

3. Faulty hydraulic travel pump

Solutions:

1. Adjust tires to manufacturer-specified PSI

2. Rebuild or replace travel motors

3.Service/replace hydraulic pumps; check fluid contamination

5. Screed Lifting Issues

For difficult/elevation failures:

Confirm engine power output

Key asphalt paver machine parts checks:

1. Hydraulic filters → Clean/replace clogged units

2. Pressure valves → Adjust settings per specifications

3. Lift control valves → Reseal/grind scratched surfaces

4. Work pumps → Replace noisy/damaged units

5.Lift cylinders → Replace seals/pistons; repair scored rods

6. Thermal Oil Heater Failure

Symptom: Inconsistent material temperature control.

Root Causes:

Insufficient fuel supply

Combustion chamber blockages

Burner/igniter failure

Solutions:

1. Verify fuel levels and supply lines

2. Clean carbon deposits; replace damaged chambers

3. Install new heating elements with calibration

7. Water Pump System Failure

Symptom: Compaction surface cooling issues.

Root Causes:

Pump impeller damage

Mineral-clogged pipelines

Electrical control failures

Solutions:

1. Replace compromised water pumps

2. Flush lines with a descaling solution

3. Upgrade waterproof wiring harnesses

If your road paver malfunctions or you need Dana Parker paver oem or aftermarket parts, please contact us.

Viverra nibh cras pulvinar mattis nunc sed blandit. Aliquet eget sit amet tellus cras adipiscing enim. Rutrum quisque non tellus orci ac auctor augue mauris. Maecenas volutpat blandit Viverra orci sagittis eu volutpat odio facilisis mauris sit. Facilisi cras fermentum odio eu feugiat pretium. Aliquam purus sit amet luctus. Euismod quis viverra nibh cras. Sed faucibus turpis in eu mi bibendum. Turpis tincidunt id aliquet risus feugiat in ante.